We have advanced and complete testing equipment to ensure the quality of our products.

Vegetable & Fruit Crate could be easily for fruit storage and convenient for transportation. The Wall thickness of our crate is 3mm, it has well loading capacity at light weight.

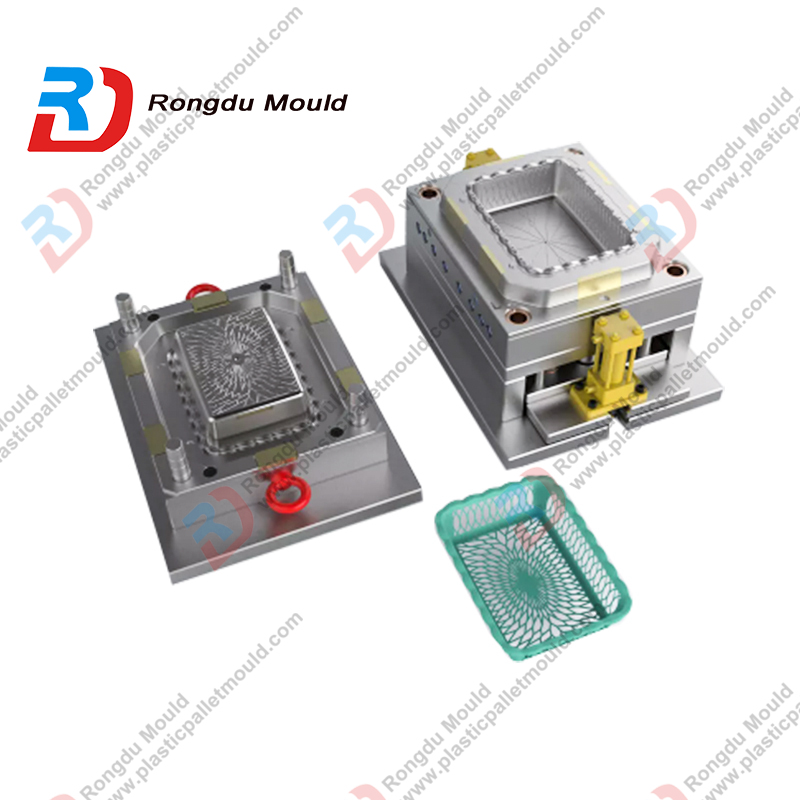

A good piece Crate need a good set Mold.

Thin-Wall Crate need scientific mold design and mold high tooling precision. In order to support customer better quality Crate mold, Rongdu Mould pay highly attention on crate mould cycle time, Our strong design team optimize as following method:

First of all, optimizing the hot runner system, Rongdu using YUDO hot runner system for Crate Mold, it is sensitive and stable for mold running. The most important thing is that more easily for maintain.

Second, optimizing the water cooling system, the diameter for water-runner is from 8-10mm, and insert beryllium copper for Deep-Rib. So that it could deeply reduce the cycle time.

Next, optimizing the ejection system, Rongdu using JUNFAN brand hydraulic cylinder, which is imported from TAIWAN. It could support super power during the mold opening, so that it could hugely reduce the cycle time. And Rongdu using 5-Axis Tooling machine to manufacture the ejection Plate & Ejection Hole, High precision Tooling could ensure the BALANCE during the ejection.

Above technologies could ensure longer mold guarantee life and stable running.

Product Basci Info:

Crate Name: High Precision Light Plastic Injection Vegetable Crate Container Turnover Box

Plastic: HDPE/PP

Crate Weight:3kg(New HDPE)

Crate type: net type crate mold, flat type crate mold, vegetable crate mold, fruit container box mold, light-weight container mold, plastic turnover box mold,logistics crate mould, storage crate mould,

Application: Fruit and Vegetable Storage Industry, Logistics Transportation Industry

Mold Name: Well Structure Hollow Type Fruit Storage Crate Container Turnover Box Mould

Certification: TUV Certification

Origin: China

Port: Ningbo Port

Mark-Name: RONGDU MOULD

Mold Info:

Mold Size: 850x700x680mm

Steel for Mold Basement: S50C#

Steel for Mold Core & Cavity: HP20,H718,2738,S136

Steel Treatment Technology: Quenching, Heat Treatment, Pre-Hardening

Mold Design Program: UG(NX), AutoCAD, SolidWorks

Hot Runner System Brand: YUDO, MoldMaster, Chinese brand

Tips of Hot Runner: 5 tips

Cooling System: inserted Beryllium-Cooper(BeCu)

Ejection System:Ejector Pin & Plate

Hydraulic Cylinder: Taiwan Brand

Mold Tooling Machine:5-Axis CNC Machine, Double-Head EDM Machine, 3-Axis Drilling Machine

Mold Tooling Tolerance: within 0.01mm

Mold Spare Part: DME/HASCO standard, it could be easily for replace and maintain.

Mold Surface Treatment: High Gloss Polishing & Texture

Mold Cycle Time: 50S

Mold Life: more than 1 Million Shoots

T0 Time: 40 days

Mold Delivery: 50 days

Transport Package: Wooden Case

Mold Guarantee:1 Year

English

English Español

Español 中文简体

中文简体