Is the process of making plastic molds complicated?

With the development of science and technology, plastic product molds have already become an irreplaceable product in our life. In our real life, plastic products have almost occupied every field. Whether it is the spare parts of airplanes, cars, ships or some toothbrush cups that are more commonly used in our daily life, there are plastic shadows. In fact, the plastic products commonly used around us are not produced by manufacturers one by one according to the drawings, but are mass-produced through plastic molds.

Before the manufacturer wants to produce a plastic product, it will make a mold for this product in advance. After the mold is completed, the manufacturer can use this mold for mass production and manufacturing. So is the manufacturing process of plastic molds complicated?

In fact, the manufacturing process of domestic plastic molds is very accurate and complicated, because in real life, plastic molds are used in the fields of various plastic products, and many plastic products must be very accurate when manufacturing, such as plastic bottle mouths. The manufacture of plastic bottle caps needs to be very precise, because if there is a slight discrepancy, it should not be combined if it is good. Therefore, we must pay attention to such problems when making plastic molds. The mold must be made very accurate to be able to make high-quality plastic products. Of course, there are not too high process requirements for those plastic products that are relatively large and relatively cheap. For example, the mold of a plastic basin does not have too strict requirements for the manufacturing process.

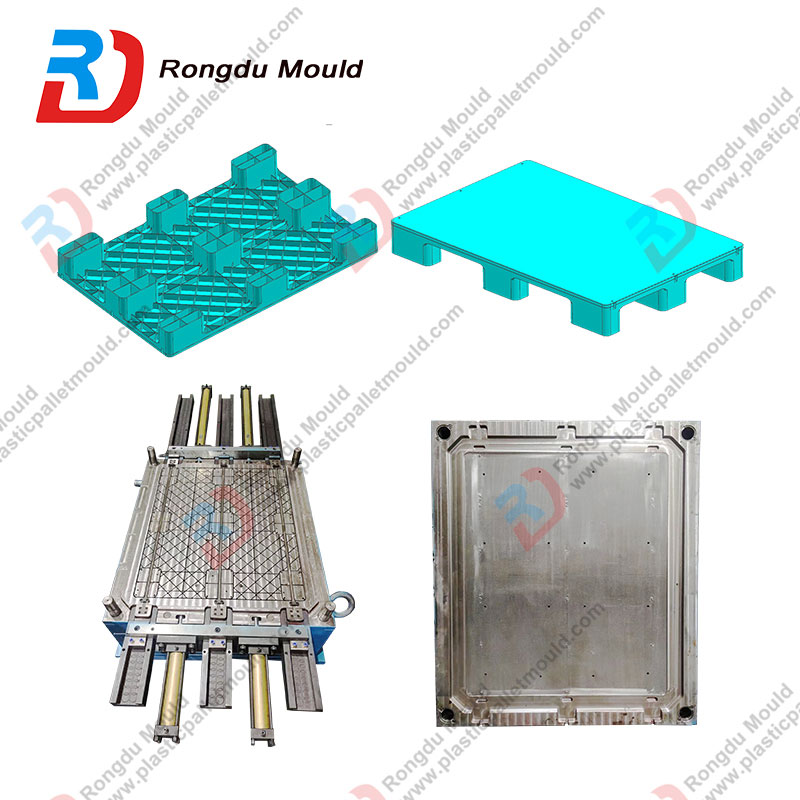

"Making Mold More Value" is our final achievement. So Rongdu Mould devote ourselves to logistics industrial for more than 30 years, we are on of the leaders at Crate Mould manufacturing.

In order to support better quality Crate, Rongdu pay highly attention on the Mold Quality. Rongdu have strong design team, we make many optimizations from hot runner system, cooling system, ejection system, and using well standard mold raw material, like HP20,H718,2738,S136 etc.

Rongdu Mould support more than 600 sets mould, including more than 100 sets crate mould annually, and won a good reputations from our regular customer.

English

English Español

Español 中文简体

中文简体